Using siemens step 7 software only one program is needed for plc and motion control making configuration and programming significantly easier and faster.

Solar panel assembly made easy.

Build diy solar panels homemade from scratch.

Creating a template putting frame together.

Important in the solar panel lamination process so film is properly aligned onto the photovoltaic cells.

A market growing at 45 percent per year looks like a good bet to get into.

The processor in the solar panel assembly machine has motion control.

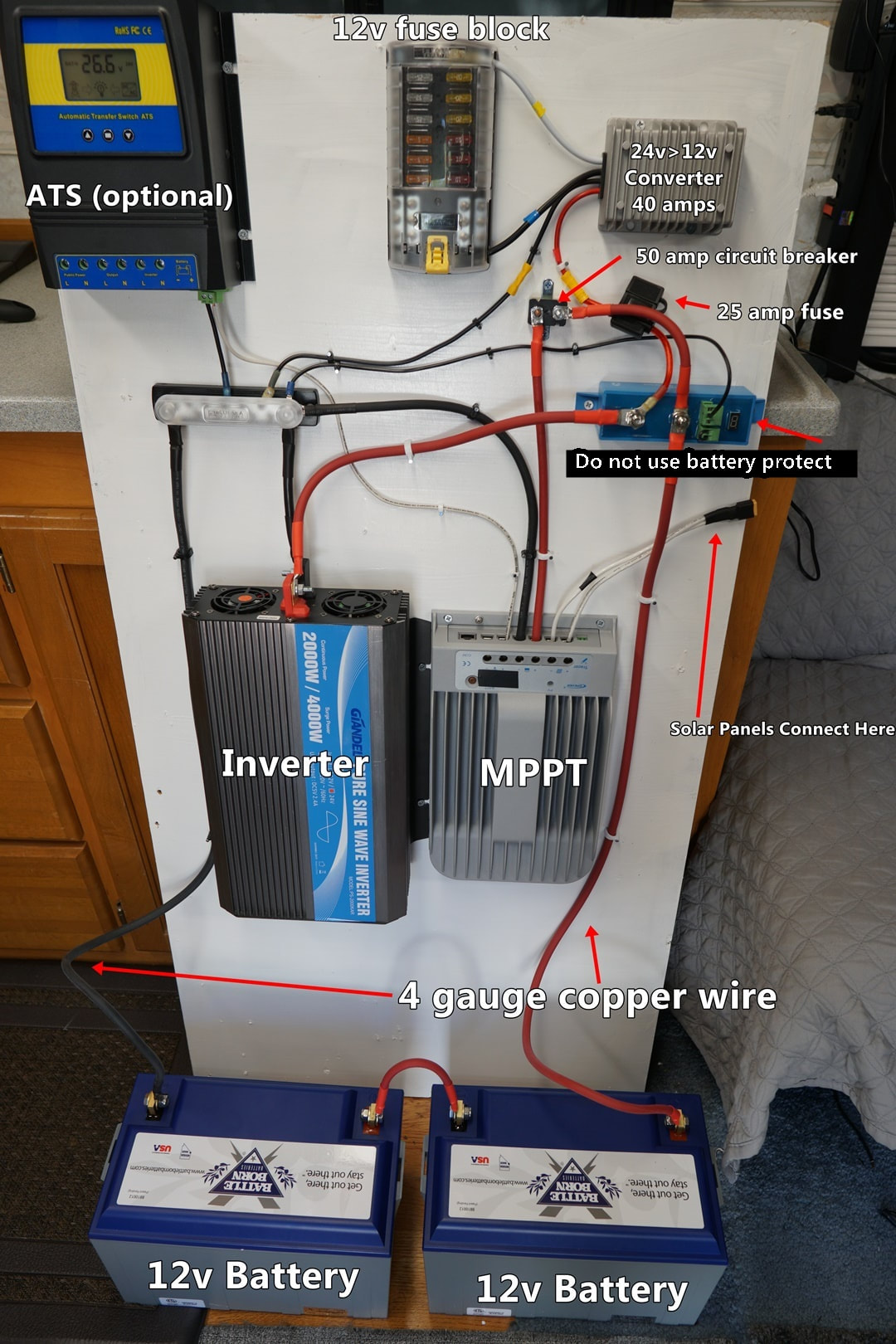

At the back sides of the solar panel a small junction box is there with a positive and negative sign for polarity.

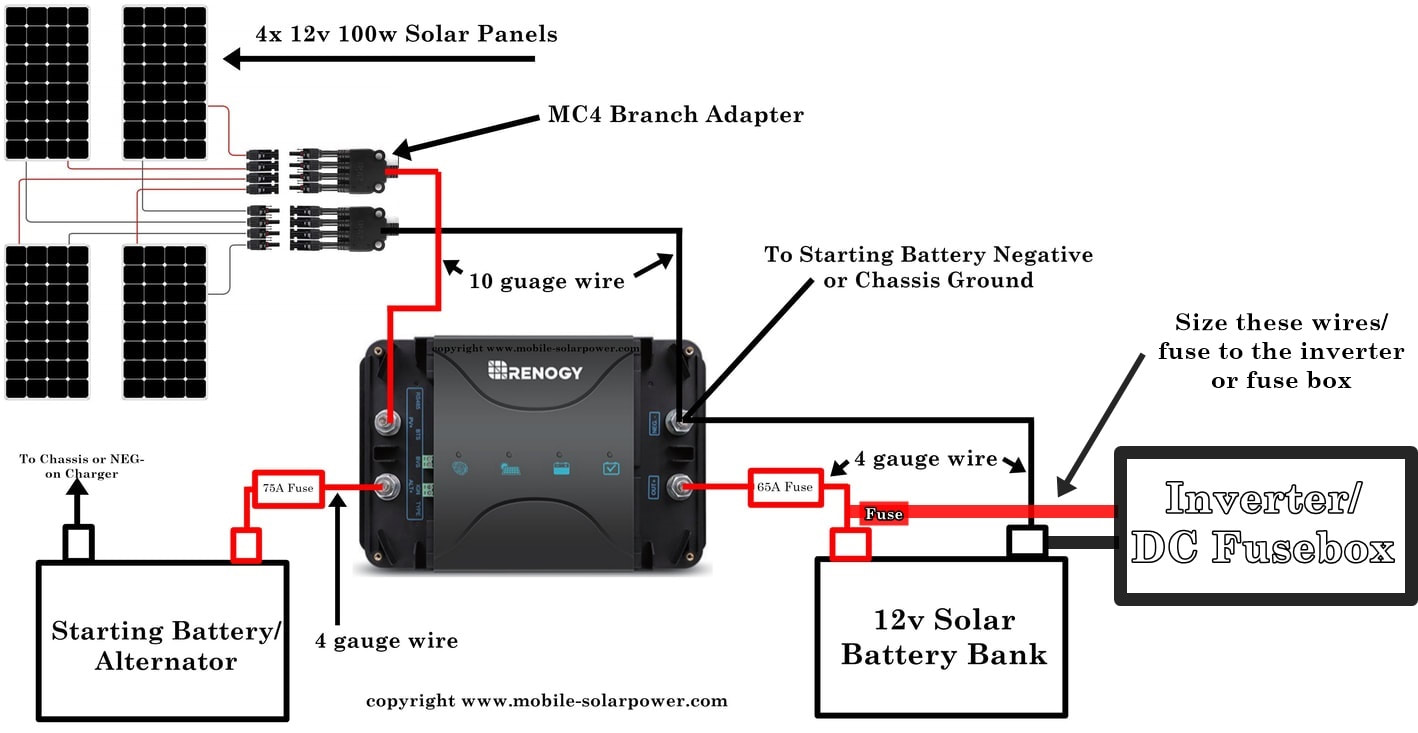

In a large size solar panel this junction box has terminal wires with mc4 connector but for small size panel you have to connect the junction box with external wires.

Assembling the solar cells.

Integrated motion and control systems from siemens provide the needed accuracy and performance.

Solar panels are relatively easy to install and are very low maintenance.

To do this we put hundreds of pounds of silicon chunks i e.

Precision manufacturing is key to producing weather resistant solar panels.

Wire the solar panel.

Match the solar panel holes with the stand platform holes and screw them together.

Rocks into a giant crucible and add a little boron called a dopant to give the silicon positive polarity.

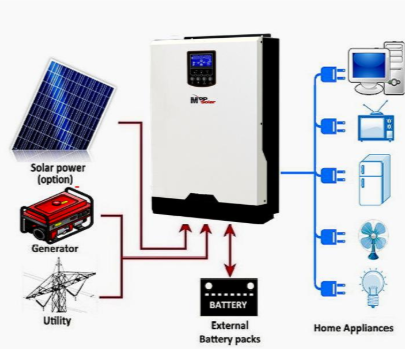

A useful characteristic of solar photovoltaic power generation is that it can be installed on any scale as opposed to conventional forms of power generation that require large scale plant and maintenance.

How to build a solar panel step 1.

Creating holes for my.

For further details a shopping list diagrams spe.

First i want to make a template for my solar cells.

It can be fun and easy to build solar panels from scratch.